I-64 Capacity Improvement Industrial Process Emissions

Replacing hot mix asphalt with foam stabilized base and emulsions, reducing mining and trucking and saving energy

Overview

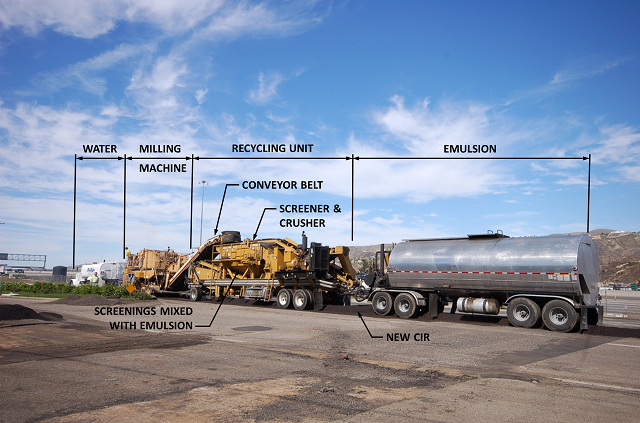

The foam stabilized base (FSB) and asphalt emulsion mixtures project aims to enlist road construction contractors in the United States with the purpose of reducing greenhouse gas (GHG) emissions during the asphalt installation process by using FSB and asphalt emulsions in place of Hot Mix Asphalt (HMA). Prior to project implementation, the road construction projects would have used typical HMA or Warm Mix Asphalt (WMA) installation which has a significant GHG emission footprint associated with the mining of virgin aggregates, trucking the virgin aggregate to the mix plant, heating the mix to 310°F, and then trucking the mixed product at high temperatures to the job site. FSB and asphalt emulsions, as compared to the baseline HMA or WMA scenario, greatly reduce GHG emissions by:Recycling the existing roadway and eliminating the need for virgin aggregate miningEliminating the need for long distance trucking of virgin aggregatesFSB and asphalt emulsions do not need to be heated to high temperatures like HMA which reduces GHG emissions related to electricity, diesel, or natural gas consumption in the mix plant and to-site delivery.FSB and asphalt emulsions are used in three pavement application processes known as Cold-in-Place Recycling (CIR), Cold Central Plant Recycling (CCPR), and Full Depth Reclamation (FDR). CIR is a method of producing FSB/asphalt emulsion pavement mixtures using one or more mobile recycling machines for milling, asphalt production, and placement in a continuous operation at the project job site that generally uses 100% RAP generated from the existing pavement at the site. CCPR is a method of producing FSB/asphalt emulsion pavement mixtures at a central mixing plant and transporting that mixture to the job site for installation. FDR is a method of producing FSB/asphalt emulsion pavement mixtures that is very similar to CIR, however the full depth of existing pavement and a predetermined depth of the underlying sub-base is recycled and mixed on-site to produce the asphalt mixture. These pavement recycling techniques enable agencies to optimize the value of in-place materials and minimize the construction time and traffic flow disruptions, as well as to reduce vehicle emissions from long traffic queues. In-place recycling reclamation also reduces the number of construction vehicles moving in and out of the construction area and neighborhood truck traffic. NCHRP Synthesis 421 documented the following benefits of pavement recycling to fix the structural distress in pavements: (a) It reduces the use of natural resources; (b) It eliminates materials generated for disposal; (c) It reduces fuel consumption; (d) It reduces greenhouse gas emissions by between 50% and 85%; (e) It minimizes lane closure times; (f) It improves driver safety by improving friction, providing lane widening, and eliminating overlay edge drop off; (g) It maintains height clearances, which eliminates the need to adjust appurtenances; (h) It addresses existing material deficiencies such as moisture damage; (i) It reduces costs of preservation, maintenance, and rehabilitation; and (j) It improves base support with a minimum of needed wearing course. The project activity quantifies the reduced GHG emissions associated with the use of FSB and/or asphalt emulsions as substitutes for HMA on asphalt construction projects. The project instances consist of existing highway roads in need of repair to extend the usable lifespan for conveying vehicular traffic. The initial project instance is located in the State of Virginia on Interstate Highway 64 (I-64) which began construction in April 2018. This group of projects is submitted following VCS methodology VM0039, Methodology for Use of Foam Stabilized Base and Emulsion Asphalt Mixtures in Pavement Application V1.0, which provides the requirements for pavement projects within the United States that use FSB and asphalt emulsions in place of traditional HMA to issue verified carbon unit credits (VCUs). This group of projects will include completed pavement projects that utilized FSB and asphalt emulsions and are located within the continental United States. Global Emissionairy, LLC is the project proponent. Ultimately, projects currently under design, construction, and future projects would be added under this project description.

Technology & Mechanisms

Technology

Roadway Recycling

Mechanism

AVOIDANCE

Project Certifications

Offset projects requires all projects on the marketplace to have its methodology, project design, and outcomes verified by an approved third party. For more on our project vetting and onboarding process, review our Trust and Safety Framework.

VCS

Verra catalyzes measurable climate action and sustainable development outcomes by driving large-scale investment to activities that reduce emissions, improve livelihoods, and protect nature.

United Nations Sustainable Development Goals

Clean Water and Sanitation

Ensure availability and sustainable management of water and sanitation for all

Affordable and Clean Energy

Ensure access to affordable, reliable, sustainable and modern energy for all

Decent Work and Economic Growth

Promote sustained, inclusive and sustainable economic growth, full and productive employment and decent work for all

Industry, Innovation and Infrastructure

Build resilient infrastructure, promote inclusive and sustainable industrialization and foster innovation

Sustainable Cities and Communities

Make cities and human settlements inclusive, safe, resilient and sustainable

Responsible Consumption and Production

Ensure sustainable consumption and production patterns

Climate Action

Take urgent action to combat climate change and its impacts

Life on Land

Protect, restore and promote sustainable use of terrestrial ecosystems, sustainably manage forests, combat desertification, and halt and reverse land degradation and halt biodiversity loss